Energy Monitoring Part Three

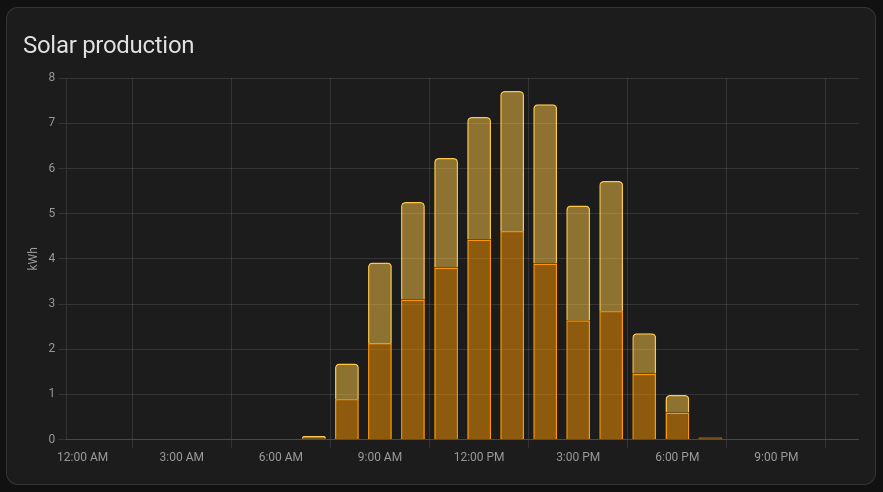

The latest graph after repairs and a new Home Assistant integration. A few clouds between 3pm and 4pm, then after 5pm a lot of clouds moved in, but otherwise things look good.

Originally when I first drafted part three of this blog post series, I thought this would be the simple process of adding monitoring of a few power-hungry devices and then a victory lap around the Home Assistant dashboard. I was way off.

Welcome to Phase Three of the monitoring process, where the gains in insights from Phase Two quickly showed me where problems were, and some needed to be addressed. We will cover a few of the relatively simple monitoring of things like appliances, but first let’s address the big problem uncovered in Phase Two.

The AP Systems Issue

When the first 22 Mission Solar 300w panels were installed in August of 2017, they were tied into the home electrical system via 11 AP Systems YC-500 microinverters. These were being monitored via an AP Systems ECU-3 which used power-line communication (PLC) to get data from the microinverters. The ECU-3 could be monitored locally or via the cloud. These devices were still the main offering of AP Systems in 2017, although the version of ECU-3’s firmware - while still the latest available for that unit - was dated 2015. The monitoring was sketchy at best, and it could take days or weeks to spot problems - particularly intermittent problems. As I got all of the data finally flowing into a dashboard on Home Assistant, very quickly I could spot odd discrepancies.

It could be a cloudless sunny day and with the AP Systems and SolarEdge monitoring showing up next to each other, I could see places where monitoring was showing little to no energy coming from the AP Systems compared to SolarEdge. The AP Systems gear seemed to be much more prone to what I call “data catch-up”. With intermittent data uploads, the totals being reported can sometimes skip a cycle or two but will “catch up” on the next cycle reporting larger amounts than normal for a single cycle. For example, I monitor my smart meter to the grid via a cloud website and sometimes it will show no usage for two hours, and then in the following third hour it shows a jump three times normal - it “catches up”. With the somewhat unreliable PLC there is some of that, and while my solar provider Kosmos Solar monitors all of their customers (and they have spotted obvious problems in the past), if something is malfunctioning intermittently this might not get caught unless you are focused only on that data. With my SolarEdge monitoring of 24 panels and AP Systems monitoring of 22 panels next to each other, it was easy to focus on oddities and see there was a problem.

As the microinverters appeared to be intermittently failing or the cabling seemed problematic and the problems seemed inconsistent with data catch-up, I made the decision to simply upgrade the lot. I called Kosmos Solar, they had the parts in stock and a free day on the schedule the very next day, and came out and performed the upgrade. Per the onsite technicians, there seemed to be problems with two of the old microinverters and also some cabling. Bingo.

The older gear’s warranty was only two years which meant it expired in 2019. However the new gear has a 10 year warranty which I feel a lot better about. So I now have 11 new AP Systems DS3-L microinverters communicating via encrypted Zigbee to a new and more modern and firmware-current ECU-R unit, which uploads data to the cloud. The cost? $5700 USD. I can take 30% off on my taxes at the end of the year which puts it at just under $4000 USD worth of impact, but still - that’s a lot of money. And this of course completely broke my local monitoring and my custom integration I had written which found the intermittent failing in the first place.

New Monitoring

For now, I knew I simply wanted to get AP Systems monitoring via Home Assistant happening. I explored a few options, but wrote yet another Home Assistant integration (actually rewrote/adapted an existing integration) using AP Systems’ cloud presence. It wasn’t what I wanted, as I prefer local monitoring, but it will do for now. Per the new ECU-R specs, one can monitor locally, but this requires connecting to the ECU-R’s WiFi hot spot which can only be activated for a short time after pressing a button on the side of the unit. Not exactly what I thought it meant when the website said local monitoring since their older models of all the ECU’s (including earlier versions of the ECU-R) had an integrated web server that was up and op all the time.

Of course other potential monitoring options exist which I might explore in the future, but each has its own problems. The microinverters use Zigbee to communication to the ECU-R, however the traffic is encrypted. There is an RS485 jack on the ECU-R, but this is considered an input to allow more expanded monitoring via the ECU-R web interface, say of a power meter. And while it is possible to MITM (Man In The Middle) the web traffic, I’m not sure I want to go to that much trouble for a process that might not work anyway (or work reliably), plus after that I’d have to engineer some type of solution to get the MITM data into Home Assistant.

Additional Monitoring

Some of the energy monitoring was quite simple. Using Shelly plugs I was able to easily set up energy monitoring of the server rack, refrigerator, the entertainment stuff in the office (television, Apple TV Plus, Playstation) and integrate them into Home Assistant. These were configured to use WiFi and work quite well. The Wallbox Pulsar Plus EV charger does have a Home Assistant integration as well as the AO Smith HPTS-50 hot water heater’s integration - both pulling from the cloud, but it works for now. In theory I could get in the wall and install a Shelly monitoring device to get active power from not just the Wallbox and the AO Smith circuits, I could also install one for the furnace (a DaikinOne setup) to get that as well. We’ll see.

Final Adjustments

OMG “final” adjustments. Well that’s funny. This is definitely a continuous work in progress, as the point of monitoring is to find things and adjust to them. Sometimes (like in the case of the AP Systems intermittent failures) it can be both expensive and turn into a complete redo of the monitoring to begin with.

Overall though, I am happy with the progress. The graphs of the AP Systems components with the SolarEdge components now match up with the experiences I remember before when I’d pull the data and graph everything in a spreadsheet before the old microinverter failures. It is obvious now that it was in fact a combination of intermittent failure of some of the AP Systems microinverters as well as intermittent monitoring failures and glitches.

There are still areas of challenges and plenty of projects both large and small ahead. But for now, outside of adding a few more power monitoring device for appliances, I’m going to watch the dashboards, tweak them, and nerd out on the data.